In a world where applied chemistry is key to industrial innovation, chemical reactors play a central role in sectors such as pharmaceuticals, energy, environmental technology, and food processing. This equipment enable chemical transformations to be carried out in a controlled way, optimizing performance, selectivity, and safety. At EDIBON, we are committed to technical training and research, which is why we offer advanced and customizable solutions for the study and experimentation of chemical reactors.

What Are Chemical Reactors?

A chemical reactor is a unit in which a chemical reaction takes place. Inside the reactor, the chemical composition of the input substances is transformed under defined conditions of temperature, pressure, mixing, residence time, and other parameters.

Reactors are designed to optimize the conversion of a desired reactant and the selectivity toward the target product, while minimizing by-products and losses. In many cases, reactors incorporate catalysts that accelerate the reaction kinetics. If such catalysts are enzymes or living organisms, the reactor may be classified as a bioreactor.

Classification of Reactors

Reactors may be classified based on several criteria:

- Mode of Operation:

- Continuous (e.g., CSTR, tubular / plug flow reactors)

- Batch (discontinuous)

- Number of Phases:

- – Homogeneous (single phase, e.g., liquid)

- Heterogeneous (multiple phases such as gas–liquid or solid–liquid)

- Thermal Regime:

- – Isothermal

- Adiabatic

Special Configurations: Reactors in series, reactors with recycle, combined configurations

Over time, reactor design has progressed from simple laboratory equipment to highly sophisticated equipment integrating control, instrumentation, and monitoring for precise optimization and advanced research.

Historical Evolution and Current Trends

The design and control of chemical reactors have evolved significantly:

Early reactor studies relied primarily on empirical testing and manual calculations. The introduction of electronic instrumentation enabled real-time monitoring of temperature, pressure, and flow.

Current trends emphasize digital integration: automatic control, data acquisition (SCADA), simulation, and optimization using algorithms and machine learning.

Sustainability has introduced new challenges, including: Low-emission processes, green chemistry, energy efficiency, recycling and distributed production models.

In this modern context, it is essential for students and researchers to work with technologies that reproduce real operating conditions, integrating digital control, precise sensors, and experimental flexibility.

How EDIBON Supports Advancement Through Its Equipment

At EDIBON, we add value by combining educational expertise with applied engineering. Our line of chemical reactors provides robust equipment for teaching, applied research, and process development, with the possibility of custom design tailored to client requirements.

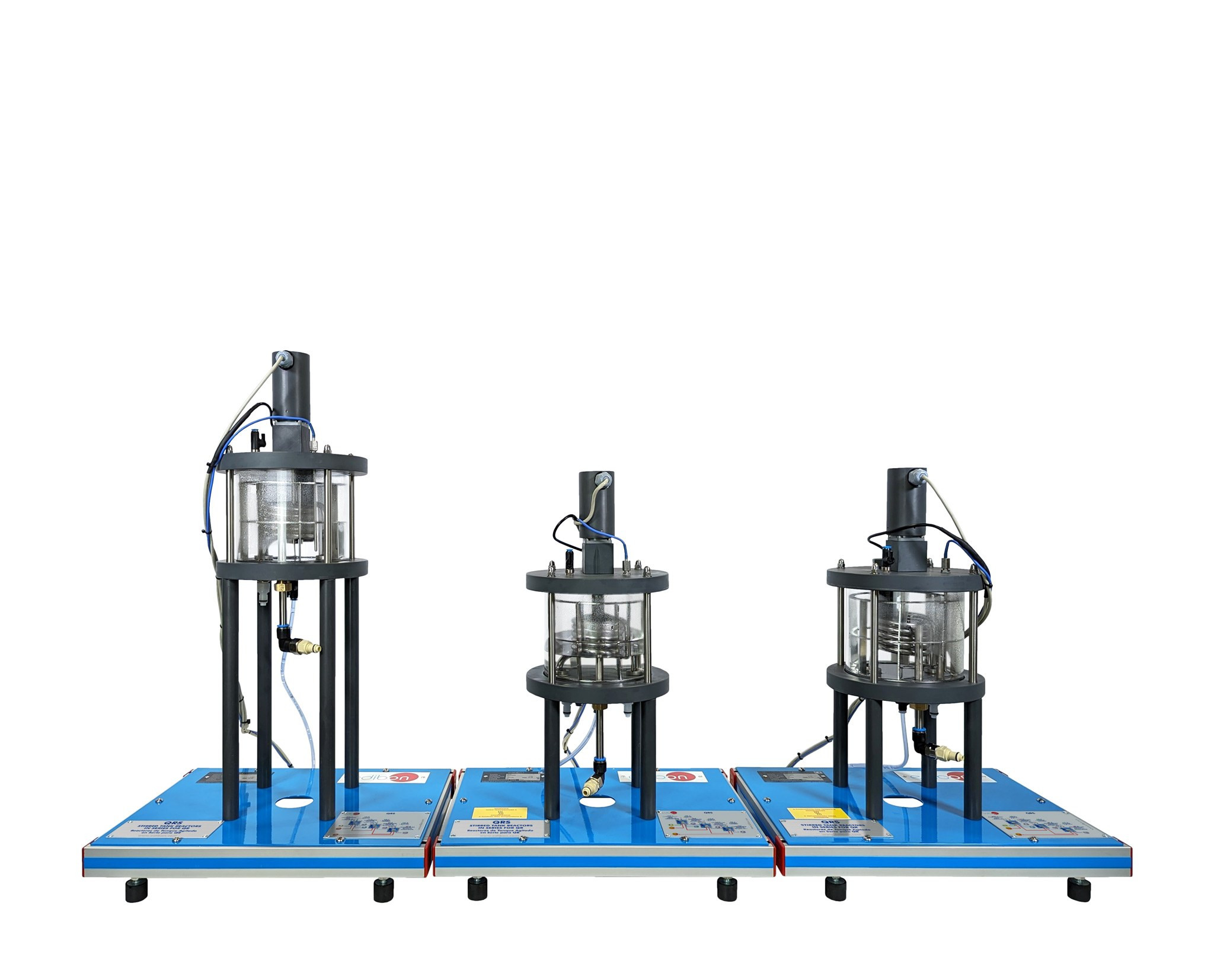

The Chemical Reactors (QR) have been designed by EDIBON to study and compare different types of chemical reactors in a simple and practical way, allowing necessary experiments to be carried out at reduced scale to understand reactor behavior.

These equipment allow comparison of multiple reactor types and the study of temperature influence and residence time, thanks to the thermostatic bath, two 1-liter tanks, and two dosing pumps (up to 3 L/min) included in the system.

Examples of Compatible Modules :

- QRCA: Continuous Stirred Tank Reactor for QR, allows the study of kinetics, reaction order, rate constants, mixing effects, and theoretical vs. experimental comparisons.

- QRT: Tubular Flow Reactor for QR, designed for studying kinetic behavior in homogeneous liquid–liquid reactions.

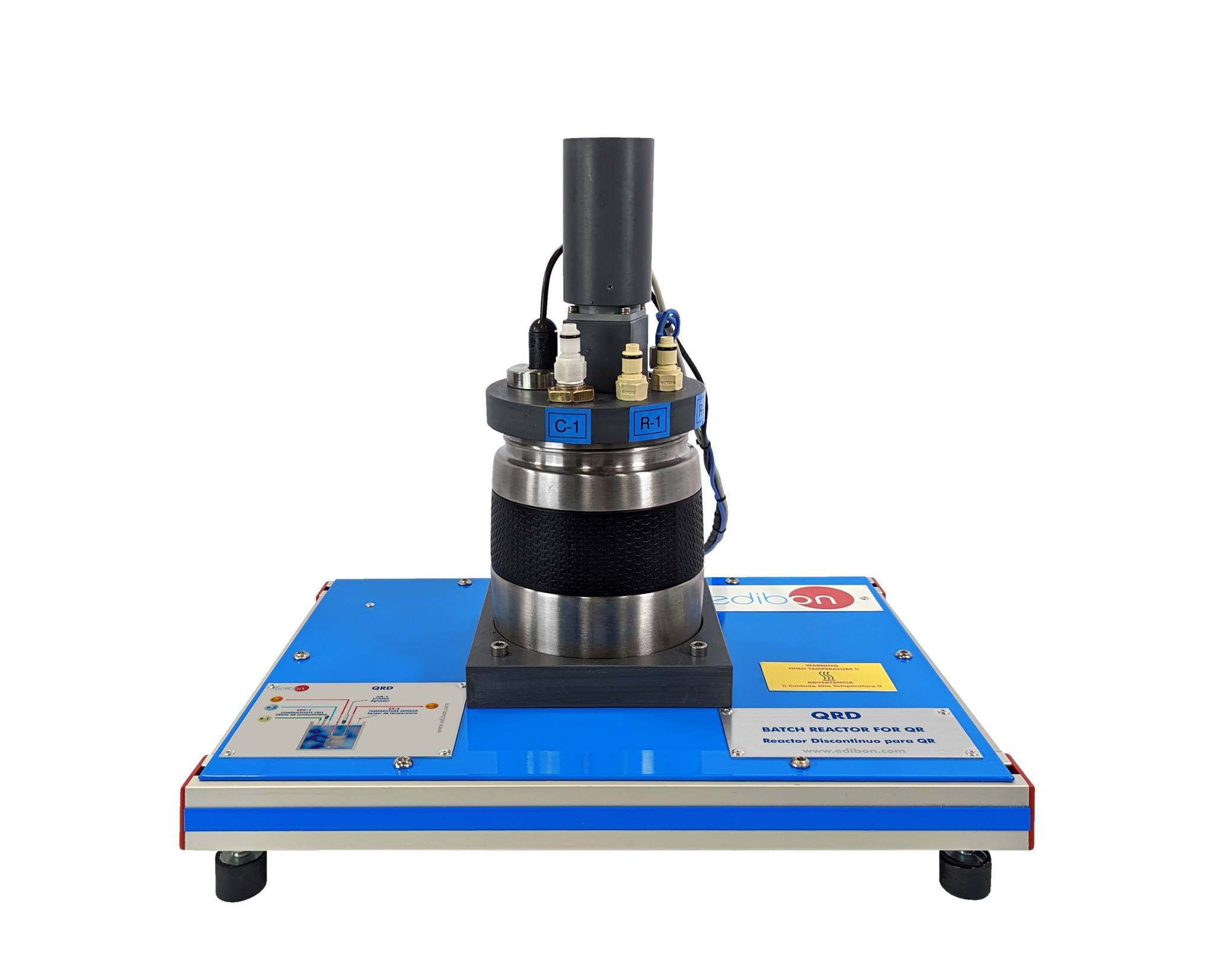

- QRD: Batch Reactor for QR, suitable for the study of homogeneous liquid–liquid kinetics and demonstration of both adiabatic and isothermal reactions.

- QRS: Series Stirred Tank Reactors for QR, allows the outlet stream of one reactor to become the inlet of the next, enabling flexible experimentation with one, two, or three reactors.

- QRL:Laminar Flow Reactor for QR, used to determine kinetic equations for reactions such as the basic hydrolysis of ethyl acetate, and to calculate related kinetic constants.

- QRP: Plug Flow Reactor for QR, enables the study of reaction kinetics and flow behavior under the assumption of negligible axial mixing.

pistón es un tipo de reactor tubular que parte de la suposición de que no hay mezcla axial de los componentes a lo largo de su longitud.

Customized Equipment and Tailored Projects

One of EDIBON’s key strengths is our ability to design fully customized reactor equipment according to client needs. We can adapt: Scale of the process, type of reaction, aggressive or special operating conditions, specific catalysts or resistant materials, additional automation requirements. This allows us to support everything from specialized laboratory studies to industrial demonstration and advanced research.

Benefits of using this equipment

Working with customized reactors offers clear advantages:

- High-level practical training with real process conditions

- Applicable research with reliable and reproducible experimental data

- Flexibility and expandability thanks to interchangeable modules

- Safe operation with continuous monitoring and multiple protection layers

- Full digital integration through EDIBON’s SCADA system, enabling data acquisition, PID control, and network-based collaborative learning

In summary

Chemical reactors are at the core of modern industrial transformation, enabling more efficient, innovative, and sustainable processes. The progression from basic laboratory reactors to digitally controlled equipment has driven major advances in chemical research and development.

At EDIBON, we are proud to support this evolution by offering high-level educational and research equipment, such as the QR series and its accessory modules, as well as fully customized solutions. With this equipment, academic institutions, R&D centers, and industries can enhance their capabilities to study and optimize chemical processes safely, efficiently, and with modern technological integration.